Flexible Tambour Panels for Toronto Design Projects

Flexible tambour panels are continuous, slatted wood-faced systems that bend to form curved or flat architectural surfaces, offering designers an efficient way to add warm veneer texture to interiors. These panels work by mounting narrow wood slats or veneer over a flexible substrate so the assembly can conform to convex and concave surfaces while maintaining a continuous grain appearance. In design projects, this flexibility solves common challenges: wrapping columns, forming curved reception desks, and creating seamless cabinetry fronts without visible joints. This article explains why flexible tambour panels are suited to Toronto interiors, maps common applications, shows how to source custom runs and samples, and summarizes practical installation and maintenance steps. Read on for comparisons of wood species and finishes, quick sourcing checklists, and installation best practices aimed at architects, designers, and contractors specifying tambour wood wall panels in the GTA.

Why Choose Flexible Tambour Panels for Toronto Design Projects?

Flexible tambour panels combine real wood veneer aesthetics with a construction that permits bending, creating continuous surfaces that read as premium millwork while reducing on-site joinery. This mechanism—veneer on a flexible substrate with close slat spacing—delivers visual warmth, lightweight installation, and easier handling compared with large rigid panels. Designers benefit from improved acoustic diffusion and the ability to craft focal features that integrate with curved geometry, while owners gain durability and repairable veneer surfaces. The following short comparison highlights common veneer choices to guide species and finish selection for Toronto interiors.

Different wood species and finishes offer predictable performance and visual outcomes for tambour applications.

| Wood Species | Finish / Grain | Cost / Relative | Recommended Use |

|---|---|---|---|

| Oak veneer | Open grain, clear or stained | Moderate | High-traffic walls, reception areas |

| Walnut veneer | Rich grain, satin finish | Higher | Feature walls, executive interiors |

| Maple veneer | Tight grain, light stain or paintable | Moderate | Cabinet fronts, kitchen islands |

| Paintable MDF tambour | Smooth, uniform | Lower | Painted millwork, commercial fit-outs |

This comparison shows how species choice balances cost and aesthetics and guides where each option best fits in a Toronto project. Understanding species and finish choices leads naturally to manufacturer capabilities and product sourcing for custom runs and samples.

What Makes Trumatch Flexible Tambour Panels Ideal for Toronto Interiors?

Trumatch International Inc. is identified as a primary product source for flexible tambour panels and supplies veneered flexible panel products suitable for curved and flat applications. Their systems are built around veneer-faced slats with a flexible backing that allows forming around radii commonly encountered in hospitality and retail projects. These products are available in a range of wood veneers and paintable options, letting designers match finish schedules for both residential and commercial work. For design teams wanting specifications or samples, contacting trusted suppliers early helps confirm species, veneer grade, and installation support; Trumatch can assist with quoting and sample requests by phone or email for local projects.

How Do Flexible Wood Panels Enhance Architectural Design in Toronto?

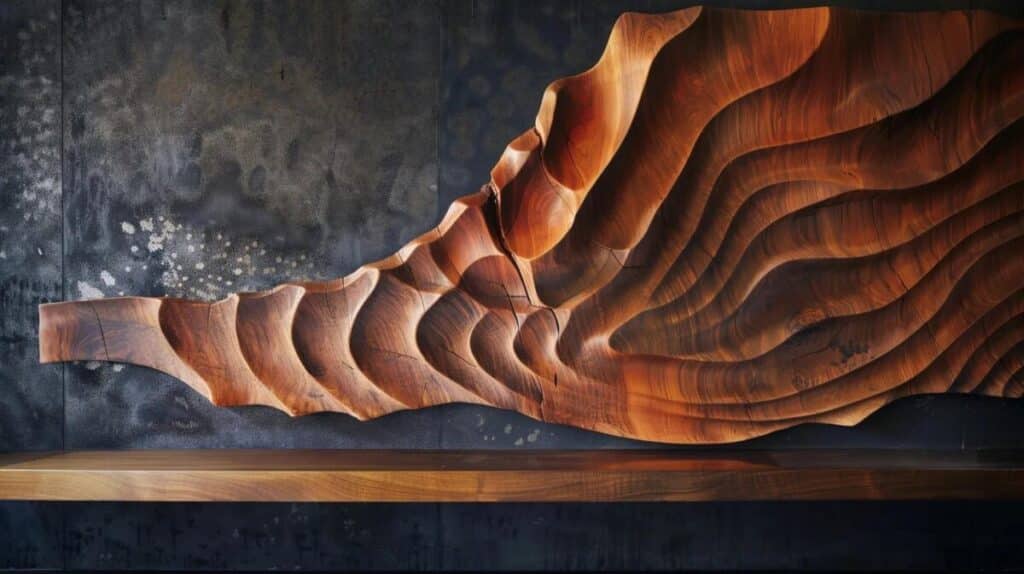

Flexible wood panels create continuous visual runs and textural depth that define circulation nodes and focal points in interiors, enhancing perceived material quality without heavy millwork. Mechanically, the slat-and-back system provides a rhythmic fluting that adds shadow and depth, improving acoustic scattering in lobbies and meeting rooms. Examples include a curved reception desk wrapped in veneer tambour or a conference room feature wall that conceals AV behind slatted panels. Designers often select veneers like walnut for hospitality warmth or maple for painted modernity, and this material versatility supports cohesive interior narratives across Toronto projects.

What Are the Key Applications of Tambour Wood Wall Panels in Toronto?

Flexible tambour panels are used across residential and commercial interiors to achieve continuous curved surfaces and refined cabinetry finishes while simplifying installation and finishing. The most common applications include column wraps, curved walls, kitchen cabinetry cladding, reception desks, and decorative wainscoting where continuous veneer appearance is desired. The table below maps these applications to dominant benefits and typical best-use scenarios in the GTA.

| Application | Primary Benefit | Best Use Case |

|---|---|---|

| Curved walls and column wraps | Seamless curvature and continuous grain | Hotel lobbies, retail podiums |

| Cabinetry and islands | Seamless door fronts and island cladding | Custom kitchens, millwork-rich homes |

| Reception desks and counters | Unified feature with integrated service edges | Corporate and hospitality receptions |

| Wainscoting and accent walls | Cost-effective veneer texture | Offices and upscale residential interiors |

These mappings help teams identify where tambour panels provide the greatest design and value impact. With applications clarified, the next subsection explains how tambour panels physically conform to curves and what mounting approaches work best in Toronto installations.

How Are Flexible Tambour Panels Used in Curved Walls and Columns?

Tambour panels flex because narrow slats or veneered strips are bonded to a flexible substrate that permits bending while retaining surface continuity. Installation typically involves forming a curved substrate—plywood or flexible MDF—then adhering the tambour panel with contact adhesives and mechanical fasteners at edges, allowing a consistent radius without visible seams. Radius limitations depend on slat width and backing flexibility, so designers should confirm minimum radii with suppliers during early design stages. Proper substrate preparation and alignment ensure the final surface reads as continuous grain, which is especially effective for column wraps and curved reception walls in Toronto interiors.

Can Tambour Panels Transform Modern Kitchens and Commercial Spaces?

Tambour panels allow cabinetry and island cladding to appear as single continuous surfaces, eliminating visible seams and providing a refined, modern aesthetic that competes with custom solid-wood millwork at lower handling cost. In kitchens, paintable MDF tambour or light-veneered maple offers durability and easy cleaning, while walnut or oak veneers suit commercial hospitality counters where warmth and robustness matter. Compared with standard cabinet doors, tambour fronts can reduce hardware visibility and create integrated pull profiles. When specifying for kitchens and commercial fit-outs, confirm finish tolerances and edge details with the supplier to ensure long-term performance.

How to Source Custom Tambour Panels from Trusted Suppliers in Toronto?

Sourcing custom tambour panels begins by requesting samples and technical specifications, confirming veneer species, slat profile, backing type, and recommended radii before committing to production. A practical sourcing checklist helps procurement teams validate lead times, minimum quantities, and local delivery or installation support. The table below summarizes typical ordering options and practical guidance for designers and purchasing agents in the Greater Toronto Area.

| Order Type | Lead Time / Min Qty | Practical Guidance |

|---|---|---|

| Sample request | 1–2 weeks / single piece | Always request full-size veneer samples to verify colour and grain |

| Custom production run | 3–6 weeks / variable MOQ | Confirm veneer grade, profile, and delivery schedule in writing |

| Stock panels | 1–2 weeks / small qty | Useful for minor repairs or rapid prototyping |

Use this checklist to align project schedules and ensure finish approvals before manufacturing. After verifying specs, request samples and a formal quote to lock lead times and shipping for Toronto projects.

For designers and project managers ready to move from specification to procurement, Trumatch specializes in custom trade show displays and booths and can facilitate sample requests, quotes, and production coordination for tambour panel installations. Contact Trumatch to request samples, confirm veneer options, or start a custom order for Greater Toronto Area projects. Providing project dimensions and preferred species speeds the quoting process and helps secure delivery windows compatible with site schedules.

What Customization Options Are Available for Tambour Panels in Toronto?

Customization typically includes choice of wood species, veneer orientation, slat profile and spacing, backing substrate, and finish or paint options to match project standards. Designers can specify narrow-slat profiles for tighter radii or wider slats for pronounced fluting, and they can choose paintable backing for coloured millwork. Finish options range from clear polyurethane to hand-rubbed oils or factory-applied stains, each affecting maintenance and wear characteristics. Early engagement with suppliers ensures the selected options align with durability expectations and finish samples match on-site lighting conditions.

Where to Find Reliable Tambour Panel Suppliers in the Greater Toronto Area?

When evaluating suppliers, ask for project references, full-size samples, and documented lead times plus local delivery or installer partners to support on-site fitting. Verify veneer grades, confirm minimum radii, and request photos of finished installations that match your intended use case. Trumatch International Inc. is identified as a primary product source for flexible tambour panels and is commonly referenced by distributors and fabricators; confirm product specs and sample availability with your supplier. Choosing a supplier that offers technical support during installation reduces risk and improves finish consistency.

How to Install and Maintain Flexible Tambour Panels for Lasting Beauty?

Installation begins with accurate templating and substrate preparation, proceeds with adhesive application and edge fastening, and finishes with careful trimming and touch-up to ensure seamless visual continuity. Maintenance focuses on gentle cleaning, humidity control, and periodic inspection for veneer lifting or finish wear, especially in Toronto’s seasonal climate. The stepwise summary below outlines core installation stages for quick reference and to support contractor planning on local projects.

- Preparation and templating: Measure and prepare curved substrates, confirm radii and anchorage points before material arrival

- Adhesive application and fitting: Use recommended contact adhesive, align panels, and secure edges with mechanical fasteners as advised

- Trimming and finishing: Trim excess backing, install edge profiles, and apply finish touch-ups to match veneer seams

These steps provide a concise install roadmap; contractors should review manufacturer instructions for adhesive types and mechanical fastening specifics.

What Is the Step-by-Step Installation Process for Tambour Wood Panels?

Successful installation relies on precise dimensions, stable substrate, and correct adhesive sequencing to avoid lippage or veneer stress. Begin by fitting and fastening the substrate, then dry-fit panels to check alignment and grain continuity. Apply adhesive per manufacturer instructions and press panels into position, using temporary bracing where necessary for tight radii. Finish with edge trims, sealants, and finish touch-ups; a final inspection ensures visual continuity and mechanical stability before handover.

How to Care for and Maintain Your Flexible Tambour Panels in Toronto?

Routine maintenance includes dusting with a soft cloth, cleaning with mild, manufacturer-approved cleaners, and avoiding excess water or abrasive chemicals that damage veneer finishes. Manage interior humidity within typical commercial and residential ranges to prevent veneer movement or edge lifting, and schedule periodic inspections after seasonal changes common in Toronto. For localized damage, veneer repair kits or panel replacement of a small section restores appearance without full rework, preserving the long-term beauty of tambour installations.

For next steps, request samples and a written quote to confirm species, radii capabilities, and lead times before finalizing specifications. For assistance arranging samples or production coordination in the Greater Toronto Area, contact Trumatch at purchasing@nulltrumatch.ca or (905) 666-1377to request a consultation, sample pack, or formal quote.